Top 11 Learning Management Systems (LMS) for Manufacturing 2025

Production lines hum constantly. Safety protocols evolve weekly. Workforce skills require continuous development. This is modern manufacturing’s reality. At Webanywhere, we’ve witnessed firsthand how maintaining consistent skills development across multiple sites, shifts, and specialities challenges even the most organised operations.

For over a decade, our team has crafted Learning Management Systems that transcend basic compliance boxes and drive operational excellence through targeted skills development. New to LMS technology? Our primer on what an LMS is offers an excellent introduction to these transformative learning tools.

The Unique Learning Challenges in Manufacturing Environments

Regulatory Compliance Demands

Manufacturers navigate a complex regulations. Stringent requirements change yearly, sometimes monthly. One missed update can trigger costly audits or production halts.

How do successful operations stay ahead? Many leverage specialised LMS platforms for continuous compliance training; our guide to the benefits of LMS for compliance training details this critical advantage.

Safety Training Imperatives

High-stakes safety protocols demand consistent implementation across diverse operational areas. A machine operator in Glasgow should follow identical safety procedures as their counterpart in Birmingham.

The Office for National Statistics reports that the UK manufacturing sector generated £456.1 billion in 2023—a 3.9% increase from 2022. This growth brings additional safety challenges as production scales.

Factory Floor Training Realities

Manufacturing environments present unique learning obstacles:

- Noisy production floors prohibit traditional instruction

- Shift patterns create scheduling nightmares

- Gloved hands require specialised interfaces

- Remote sites demand standardised knowledge delivery

These challenges require purpose-built solutions rather than generic corporate training platforms. Before selecting a system, review our checklist of things to consider when choosing an LMS for your business. Let’s get into the top manufacturing LMS solutions..

Top UK Manufacturing LMS Systems for 2025

1. Webanywhere Manufacturing LMS

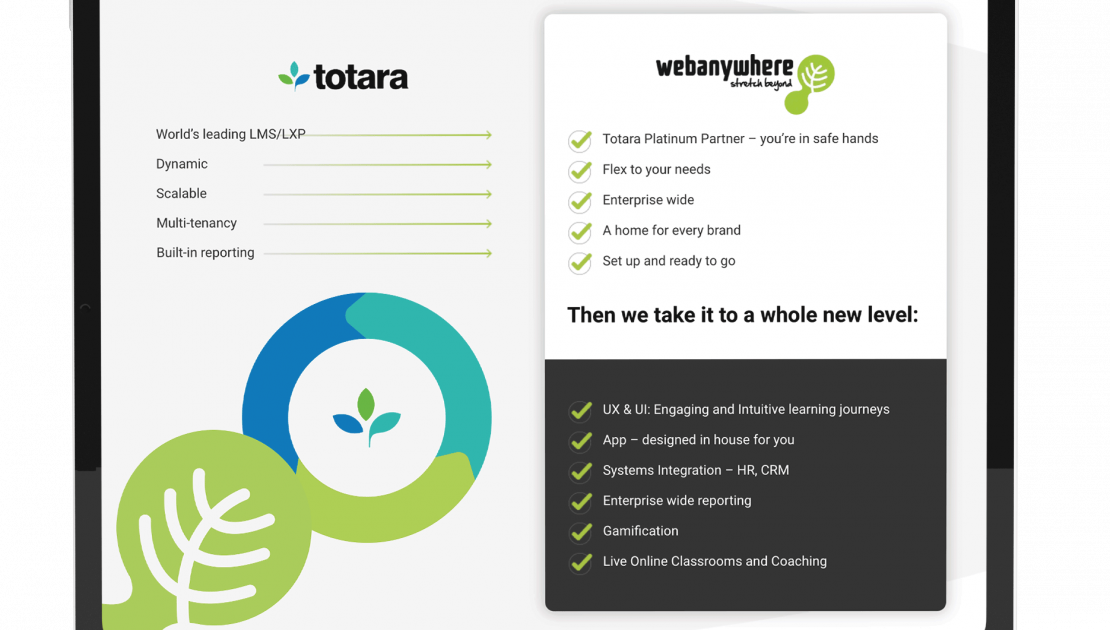

Our platform tackles complex production environments with specialised features unavailable in generic systems. We’ve built our manufacturing LMS specifically for industrial settings, not adapted from corporate or academic platforms.

Key differentiators:

- SCORM-compliant course delivery with robust certification tracking

- Machine-specific QR code training access

- Offline learning with automatic synchronisation when connectivity returns

- Full audit trail functionality for regulatory compliance

Curious about training standards? Our pos explaining the difference between AICC, SCORM, and xAPI covers the technical aspects.

Our integrations with ERP/HR tools enable seamless workforce management while mobile access supports learning on the go. Discover more benefits in our guide to mobile learning management systems.

2. Cornerstone Learning (OnDemand)

Enterprise-grade LMS focusing on continuous skill development and compliance management. Their virtual/mobile platform scales globally (used in 150+ countries and 35 languages). While robust for global enterprises, it lacks some manufacturing-specific features in specialised platforms.

3. GyrusAim LMS

Cloud LMS with strong compliance and technical training tools. Their streamlined certification tracking works well for regulated manufacturing segments but misses shop-floor specific capabilities that many industrial clients require.

4. LearnUpon LMS

This user-friendly cloud LMS serves mid-market to large organisations with over 1,500 customers. Good general features, but lacks the manufacturing-specific functionality needed for industrial environments.

5. Learningbank (Manufacturing & Production)

Digital platform tailored for frontline and manufacturing environments with emphasis on safety, quality and hands-on training. Solid European option, though UK manufacturers typically need deeper localised compliance capabilities.

6. SAP Litmos

A cloud LMS delivering mobile-first learning with a vast library of video-based content. Highly scalable and used in 150+ countries with 35 languages supported. Good video capabilities, though our clients typically require more comprehensive manufacturing-specific features.

7. SkyPrep LMS

A cloud LMS known for ease of use, with over 1,000,000 active learners. Features strong compliance/certification support that simplifies compliance training with automatic certificates. User-friendly, though lacking the manufacturing depth our platform provides.

8. eloomi (Ceridian Dayforce Learning)

An all-in-one LMS and performance platform that combines training, skills management and performance reviews. Offers multilingual compliance training with deployment in 10+ languages. Strong HR integration but without the factory-floor focus our manufacturing clients require.

9. Eurekos LMS

A cloud LMS focused on extended enterprise training for customers and partners. Emphasises product and partner education with advanced certification workflows. Suitable for customer training, but not specifically designed for manufacturing operations like our platform.

10. Kallidus Learn (formerly Saffron)

A UK-based SaaS LMS emphasising compliance and performance. ISO/SOC2 certified and integrates learning with talent management. A good UK option, though our manufacturing specialisation offers additional value for production environments.

11. Empowered LMS (Paradiso)

A cloud/AI-enhanced LMS targeting enterprises and the extended enterprise. Designed for large deployments with features for compliance paths and multi-tenant portals. Strong enterprise capabilities but without our manufacturing-specific features.

How Our Manufacturing-Focused LMS Transforms Operations

As one of the UK’s manufacturing LMS specialists, we’ve designed our platform from the ground up to address the unique challenges production environments face. Our years of experience working exclusively with manufacturers have allowed us to develop features that generic LMS solutions simply cannot match.

Our manufacturing-specific capabilities include:

- Advanced compliance frameworks pre-configured for UK manufacturing standards

- Machine-specific training modules are accessible via QR codes placed directly on equipment

- RFID badge integration for seamless access to relevant training materials

- Offline capability that synchronises when connectivity restored

- Real-time skills gap analysis linked to production KPIs

As manufacturing continues its digital transformation, factories and manufacturing facilities are poised to pass the tipping point of smart factory adoption, moving from occasional or sporadic implementation of smart manufacturing equipment to more full-fledged systems. This evolution necessitates more sophisticated training solutions.

While other platforms have their strengths, our comprehensive approach consistently delivers the most complete solution designed for UK manufacturing excellence.

What Makes Manufacturing LMS Different? Key Features for Factory Training

Through our years of specialisation in manufacturing training, we’ve identified key differentiators that set production environments apart from typical office-based learning scenarios:

Shop floor accessibility represents perhaps the most visible difference. Workers don’t sit at desks, so they need training accessible from tablets, kiosks and mobile devices that can be used with gloves or in noisy factory environments, something our platform excels at providing. Titus Learning shows, “Mobile access is a must. You need to ensure that you can view the LMS via a smartphone but also that it’s easy to complete key activities and tasks using a mobile interface.”

Compliance traceability forms another cornerstone of our manufacturing-focused system. When auditors arrive, our clients need instant, complete training records for:

- Health and safety certifications

- Quality standard adherence (ISO, HACCP, GMP)

- Machine-specific competencies

- Regulatory compliance evidence

As Totara notes, a manufacturing LMS must “ensure compliance across your entire organisation and extended enterprise to keep everyone safe” and “equip your people with machinery-specific knowledge to protect the wellbeing of workers.” Read more about how our system helps with these requirements in our piece on why compliance training matters.

Multi-site consistency provides the third critical differentiator in our approach. Our system ensures the same procedure is followed at your Glasgow plant or your Birmingham facility, with localised variations only where necessary. This standardisation directly impacts product quality, customer satisfaction, and market position.

Offline learning capabilities are essential for manufacturing environments where network connectivity may be restricted due to safety protocols or building infrastructure. Our system synchronises training progress when connectivity is restored, allowing continuous learning even in challenging industrial settings. Learn more about different training approaches in our guide to types of blended learning.

Is Your Manufacturing Training Ready for 2025? Factory Floor Learning Trends

Many manufacturing organisations continue operating with training approaches developed decades ago, increasing risk as technology and regulations evolve. Research from ATS, shows 2025 is expected to see “a leap forward in so-called ‘cognitive automation,’ which uses advanced AI to optimise automation on the fly based on machine learning algorithms.” This technological evolution demands equally advanced training systems for factory workers.

The AlphaSense platform notes that “2025 is set to be a pivotal year for the global manufacturing industry, with a strong focus on incorporating innovative technologies to enhance efficiency and safety.” Manufacturing companies that embrace these innovative technologies will see significant gains in efficiency, productivity, and overall competitiveness. Learn more about these changes in our post on how AI is redefining roles and skills in L&D.

From our experience working with hundreds of UK manufacturers, we’ve identified these warning signs that your current training approach needs updating:

- Paper-based processes: Tracking certifications involves spreadsheets or paper records rather than a digital LMS

- Inconsistent procedures: Different sites follow slightly different procedures for identical tasks

- Lengthy onboarding: Bringing new staff up to speed consistently takes weeks rather than days

- Compliance incidents: You’ve experienced safety or regulatory issues attributable to training gaps

- Scattered resources: Training materials exist in multiple formats across different locations

Hurix say employee performance can increase by 15 to 25% when they are allowed to learn at their own pace with effective digital learning systems. The acceleration of technological change within manufacturing creates another compelling reason to modernise training systems. As smart machinery, automation, and data-driven processes transform production floors, workforce skills must evolve in parallel.

Selecting Your Manufacturing LMS

Choosing the right system involves balancing several critical factors specific to manufacturing environments. Technical considerations must include UK/EU data compliance capabilities necessary in the post-Brexit regulatory landscape. Integration capabilities with existing production, quality, and HR systems prevent information silos and reduce administrative overhead. Mobile and offline accessibility remains essential for factory environments where connectivity may be limited or restricted.

Business priorities naturally influence the selection process. We work with our clients to ensure implementation timeframes align with operational realities. Many of our manufacturing clients wisely avoid deploying new systems during peak production periods. We help calculate the total cost of ownership, including not just platform licensing, setup, administration, and content development expenses. Our platform’s scalability ensures it can accommodate expanding operations without disruptive migrations.

The sometimes overlooked user experience perspective deserves equal consideration. Our intuitive interface, requiring minimal training, removes barriers to adoption, which is significant for diverse manufacturing workforces. Our accessibility features ensure all team members can engage effectively, while our language support accommodates the increasingly international nature of British manufacturing teams.

Future of Manufacturing Training Through Learning Management Systems

We’re leading the way as forward-thinking manufacturers leverage our platform increasingly sophisticatedly, extending beyond basic compliance requirements. According to Deloitte’s 2025 Manufacturing Industry Outlook, manufacturers are prioritising “targeted investments in their digital and data foundation to boost innovation and tackle ongoing skills gap and supply chain challenges.” This aligns perfectly with our approach of connecting training completions to production metrics to create visibility into skills’ impact on operational outcomes.

Industry analysts at Grand View Research report that the rising popularity of gamification in the LMS industry is adding elements such as badges, points, and leaderboards to drive user engagement, particularly among younger learners. We’re also at the forefront of immersive technology integration, with AR/VR training for complex equipment operation, reducing risk and learning time. These approaches prove particularly valuable for low-frequency but high-consequence tasks where traditional practice opportunities are limited.

Our social learning tools enable the development of internal knowledge networks, capturing the expertise of experienced staff before retirement and facilitating mentorship across shifts and locations. This aligns with industry-wide trends identified by Talented Learning, which notes that customisable configurations in LMS platforms are essential to meet specific organisational needs across onboarding, product training, and leadership development.

A 2025 report by Research.com, 80% of employees believe personalised learning is important in training, and 67% of leaders refer to worker skills, behavioural patterns, motivations, passions, and work styles to personalise work experiences and practices. Explore this concept further in our guide on the benefits of personalisation in e-learning. A forward-thinking LMS isn’t just about compliance, it’s about creating competitive advantage through superior workforce capabilities in an increasingly challenging manufacturing landscape.

As ProProfs Training notes, a manufacturing LMS is essential for “safety & compliance training, skill development, and policy & procedure training” in industrial environments. Our solution delivers these critical capabilities while addressing the unique challenges of the factory floor environment.

Take the Next Step with Webanywhere’s Manufacturing LMS Solution

While other systems offer valuable capabilities, only our platform was built from day one was built with manufacturing in mind rather than adapted from general-purpose training platforms. This manufacturing-centric approach reveals itself in countless practical features that address the unique challenges of production environments, factory floor training, and industrial compliance requirements.

Learning Light say many manufacturers are facing a severe gap between the talent they need and what is available in the labour market, with this talent gap expected to increase shortly. An effective LMS can help bridge this gap by making training more accessible, engaging, and relevant to the specific needs of your production environment.

The transition to a modern manufacturing LMS represents a significant opportunity to transform training effectiveness and overall operational performance. Our team of UK manufacturing specialists is ready to help you approach this evolution strategically, aligning learning systems with broader business objectives to achieve impressive results.

Contact us today to discuss how our purpose-built manufacturing LMS can help your business thrive in 2025 and beyond.

FAQs —-

What makes manufacturing LMS different from standard corporate training systems?

Manufacturing LMS platforms address unique industrial challenges: shop floor accessibility, compliance documentation, multi-site consistency, offline capabilities, and machine-specific training modules. They prioritise practical skills development in environments where traditional training methods fail.

How quickly can we implement a manufacturing LMS?

Implementation timelines vary based on organisation size, complexity, and integration requirements. Typical deployments range from 6-12 weeks for mid-sized manufacturers. Our team can provide a personalised timeline after understanding your specific needs.

Can a manufacturing LMS integrate with our existing ERP/HRIS systems?

Yes. Modern manufacturing LMS platforms offer robust API connections to major ERP, HRIS, and production management systems. This enables automated user management, synchronised training records, and comprehensive reporting across your technology ecosystem.

How do we measure ROI from our manufacturing LMS investment?

Key performance indicators include reduced onboarding time, decreased compliance violations, improved quality metrics, lower accident rates, and reduced production errors. Our system provides detailed analytics to track these improvements against your implementation investment.

What types of training content work best for factory environments?

Short, focused microlearning modules excel in manufacturing settings. Video demonstrations, interactive simulations, and mobile-accessible content prove most effective. Successful implementations blend digital learning with hands-on practice for optimal skill development.

How does a manufacturing LMS support multi-language workforces?

Our platform supports 35+ languages with automatic content translation and localised interfaces. This ensures consistent training delivery across diverse workforces while maintaining regulatory compliance in different regions.

What future LMS innovations should manufacturers anticipate?

Watch for AI-driven learning paths, expanded reality (XR) training simulations, predictive skills gap analysis, voice-activated learning, and IoT integration with production equipment. Our development roadmap incorporates these innovations to keep your workforce ahead of industry changes.